H.A. Engineering & Machinery reputed pioneer in plastic technology and processing machinery manufacturer, We are a technology company with a strong focus on research and development, Manufacturer of different types of Single, Twin& Conical screw-barrel with High Accuracy, reliability & optimization process.

Read more

Ethical Business Approach

To be recognized globally as the market leader for possessing a perfect blend of commercial & technical expertise and maintaining a proven track record of offering an excellent service.

Customer Centric Policies

To transform into a consistently growing company that constantly strives to offer the finest quality service and achieve the most desirable results.

True Responsiveness

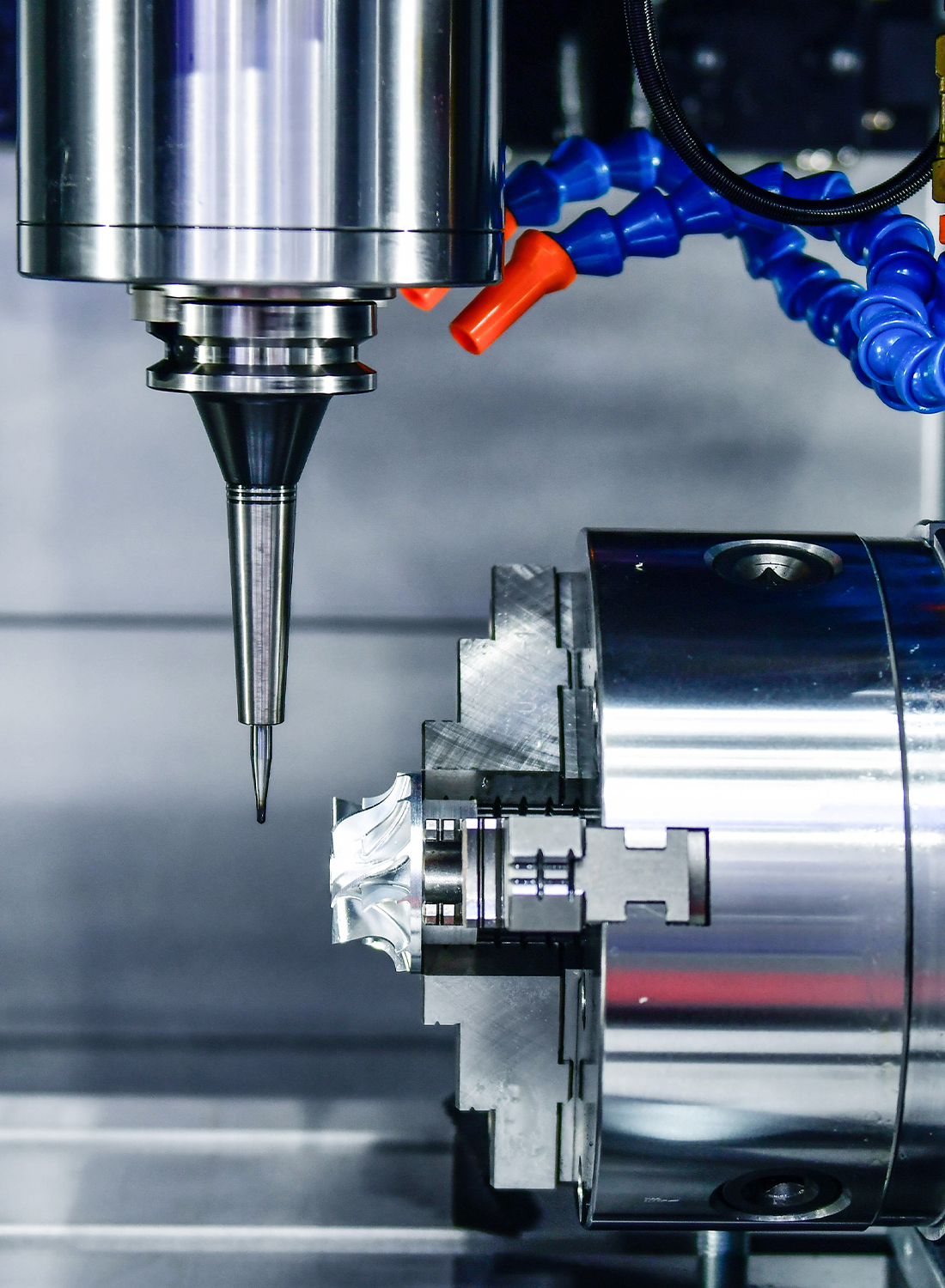

H.A. Engineering quality control department employs high precision inspection instruments to conduct incoming inspections, on-process inspections and final product inspections.

To be recognized globally as the market leader for possessing a perfect blend of commercial & technical expertise and maintaining a proven track record of offering an excellent service.

To transform into a consistently growing company that constantly strives to offer the finest quality service and achieve the most desirable results.

H.A. Engineering quality control department employs high precision inspection instruments to conduct incoming inspections, on-process inspections and final product inspections.

We aim towards going beyond the set standards of excellence to achieve stakeholder and customer happiness at all times.